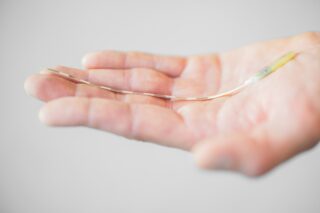

A new fully automated orthodontic printer that can produce 500 clear aligners in 24 hours is now available for large labs and dental production companies across the globe. It was unveiled in Europe at the International Dental Show (IDS) in Cologne, Germany in March.

The Element’s technology developed by Structo uses a unique panel light and mask technology to deliver 3D dental products in unbeatable time. It is currently the world’s fastest aligner printer and can produce up to 170 models per working day and 500 in 24 hours of production time, according to the company. Doug Statham, Structo’s global sales and marketing lead, said: “It is the first fully automated orthodontic printer and will produce up to 500 models in 24 hours. It will print, wash and dry the products all in one.”

Structo is a Singapore-based company specialized in 3D dental printing solutions, providing products to dental labs and manufacturers all over the world. After over three years of trial and experiment the company has developed a unique technology, called Mask Stereolithography (MSLA). It enables their dental 3D printers to achieve speeds much higher than conventional SLA models. This means labs have higher output with lower costs, the company says.

“It is the first fully automated orthodontic printer and will produce up to 500 models in 24 hours. It will print, wash and dry the products all in one.”

MSLA technology uses a panel light source array and a “digital mask” to control which regions in the printing plane are illuminated by the light source below. This mask can be transparent or opaque and it controls which area of the build platform is illuminated at any given time. Precision light is passed through to strike photocurable resin and create the mold. A solid layer of the printer object forms where the light touches. This process repeats itself until the entire object is successfully printed.

The Elements printer is now available to order. The automation aims to cut out the needs for post-processing employee labor, without reducing the quality of the end product. It is well suited to the high volume output of large labs and clear aligner manufacturing.

The German clear dental aligner brand ClearCaps has been using Structo technology to accelerate its large volume manufacturing operations for over two years. “We always strive to be at the forefront of the latest technology to help us deliver superior treatment outcomes,” Jesse Bartels, founder of ClearCaps, said previously. “To meet our high quality, high volume manufacturing requirements, we look for a printer that can deliver the throughput we require over time as we rapidly increase our production volumes. When we came across Structo’s impressive MSLA technology we decided to get on board.”