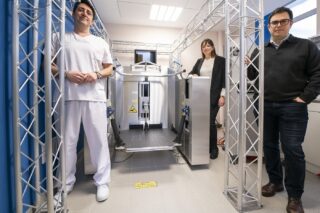

Tissue engineering company CTIBiotech makes three-dimensional human tissue models that are as close as possible to what is happening in the human body. After signing an agreement with Transgene, they now 3D print human tumors to accelerate the development of new cancer treatments such as immunotherapies. We talked to Nico Forraz, Chief Executive Officer at CTIBiotech.

MedicalExpo e-magazine: How do you print tumors in 3D?

Nico Forraz: First of all, we collect biological samples in cancer centers and we transport them to our laboratory. Just before a tumor—which is the size of a pinhead—is incinerated and thrown in the garbage, we ask patients and health teams to recover these tumors so that they can be dissociated, sorted and amplified.

To do this, all the cells that make up the tumor are separated. We have cancer cells, cancer-associated fibroblasts, immune cells that unfortunately do not recognize the tumor, and vascular cells that feed the tumor. We sort them according to each cell type and then each cell type is amplified, meaning their number available is increased. To do this we have developed tissue engineering methods to find bio-inks or biological materials that are compatible with each cell type. From 10,000 cells we will be able to make billions of them.

“Today, we are able to print 100 of them from a single tumor.”

From each cell type we create bio-cartridges. Then we design the size of the tumor we want to print. It is a whole computer-aided design phase like in the mechanical or automotive industry. This gives instructions to our 3D printer that will create serial micro tumors that look like the original tumor and have the same biological properties. They’re just a little smaller. Today, we are able to print 100 of them from a single tumor.

MedicalExpo e-magazine: What are the advantages of using 3D printing compared to other engineering techniques?

Nico Forraz: Before we used to do everything manually. 3D printing is a path we embarked on five years ago because we realized, particularly for pharmaceutical developments, that it was necessary to have tens or even hundreds of identical tissues to test different convictions in vitro.

Thanks to 3D printing we gained in precision: we can deposit different cellular groups at different places in a 3D structure in a very precise way. We also gain in reproducibility. When we create a biological ink with cells, we know that exactly the same amount of cells will be used, it is extremely homogeneous. Between tumor#1 and tumor#48, for example, there is almost no difference in terms of cellular quantity. Whereas by hand, even if we have very well trained researchers, we can still have small variations that mean that at the moment T0 when you start your drug test you do not have the same biological model.

“Another advantage of 3D printing is the productivity. An experienced researcher producing a plaque with 24 tumors, for example, will take one afternoon to do so. With 3D printing it will take between 4 and 7 minutes.”

Another advantage is the productivity. An experienced researcher producing a plaque with 24 tumors, for example, will take one afternoon to do so. With 3D printing it will take between 4 and 7 minutes. As a result, we prefer to put the know-how of our experienced researchers into developing biological inks or methods to ensure that the cells are in the right positions and that the models are predictive rather than spending a lot of time doing manual assembly where we will still have some minor variations between the models.

MedicalExpo e-magazine: What does your partner Transgene intend to do with these 3D printed tumors?

Nico Forraz: Transgene needs to develop immunotherapies as close as possible to how the patient will react. The goal is to re-educate the patient’s immune system against his cancer. Transgene is currently working on a complication of colorectal cancer which is the development of metastases in the liver. The idea is to be able to predict as soon as possible if a drug candidate or biotherapy has a chance of being effective when we do the clinical test.

Transgene was interested in being able to take a primary tumor, multiply the cells and print them in series to test the models. We can have simple models only with cancer cells and more complex models with the addition of cells from the tumor environment.

“The point of this is to move towards personalized medicine. It is a big trend in the pharmaceutical industry today. We realize that treating ten thousand people with the same therapy when they have biological differences between them is not necessarily the best method.”

Another development that we are also seeing in the future is the creation of personalized medicine platforms. One could imagine doing the same for every cancer patient in the future and allowing oncologists in cancer centers to have a single therapy test or combination therapy test in a matter of weeks to tailor treatment to each patient. The point of this is to move towards personalized medicine. It is a big trend in the pharmaceutical industry today. We realize that treating ten thousand people with the same therapy when they have biological differences between them is not necessarily the best method.

MedicalExpo e-magazine: You are also working on the same technology to 3D print skin models.

Nico Forraz: Yes we also have applications in dermatology, cosmetics and medical devices (liquid dressings, light-based devices to repair the skin, etc.) to repair the skin. The important thing is that with our technology the tests will give a predictive answer that is better than if we did a test on animals for example.

Like in the case of tumors, a sample of skin is collected. Then the dermis is separated from the epidermis. In the epidermis, the keratinocytes are isolated and amplified separately. In the dermis, we will take the fibroblasts and make them amplify separately, we will take the sebocytes and make them amplify separately, then the melanocytes that bring the same pigment, and so on. Then we will create a keratinocyte cartridge, a fibroblast cartridge, etc. From this, we will recreate our complete skin model by 3D printing.

“Instead of having a small fragment of biopsies on which to perform an ex vivo test, for example, we are able to print hundreds of them. As a result, you can multiply the tests by culturing the printed skin samples and compare many possible conditions.”

Instead of having a small fragment of biopsies on which to perform an ex vivo test, for example, we are able to print hundreds of them. As a result, you can multiply the tests by culturing the printed skin samples and compare many possible conditions: with stress, without stress, UV rays, pollutants, allergens, etc. Being able to model a wide range of conditions makes it possible to see if a treatment, an ingredient, a formulation or a medical device is effective and what its effects are and to do so at the same time on a large quantity of skin.