With personalized, regenerative medicine continuing to grow in popularity, the rapid evolution of 3D bioprinting technology is giving doctors and researchers the tools to better target treatments and improve patient outcomes. US-headquartered EnvisionTEC, one of the few 3D printer companies in the world whose products are being used for the production of final end-use parts, is a market leader in the development of bioprinting solutions. The company’s 3D-Bioplotter is a world-leading bioprinter used for research in over 300 peer-reviewed scientific and medical papers. MedicalExpo e-magazine caught up with Madalyne Ridella, EnvisionTEC’s Biomedical and Service Application Engineer, to find out more.

Can you give us a quick overview of biofabrication and 3D bioprinting? What kind of medical challenges are these processes helping to overcome?

Madalyne Ridella: Biofabrication is the automated production of complex biological products such as tissues and organs to address health challenges in medicine. It uses the principles of additive manufacturing—often termed 3D printing—in a “bioprinting” process that combines living cells, matrices, molecules and biomaterials into a single construct that can replace a diseased or injured tissue.

3D bioprinting is advantageous because you can create complex scaffolds to aid in a variety of applications. A major challenge in the medical field is organ failure and there are not as many available donors as there are patients. Bioprinting could help resolve this issue by creating functionalized organs and medicines that are patient-specific.

Can you tell us about the 3D-Bioplotter? How does it work and what are its most innovative features?

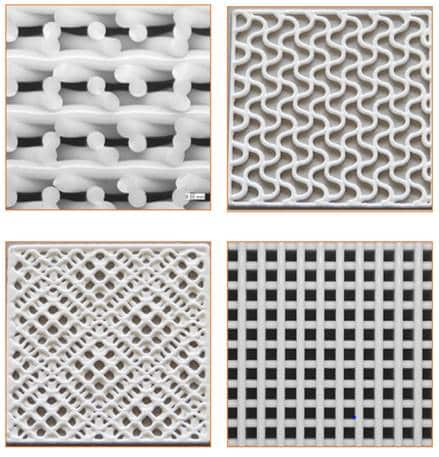

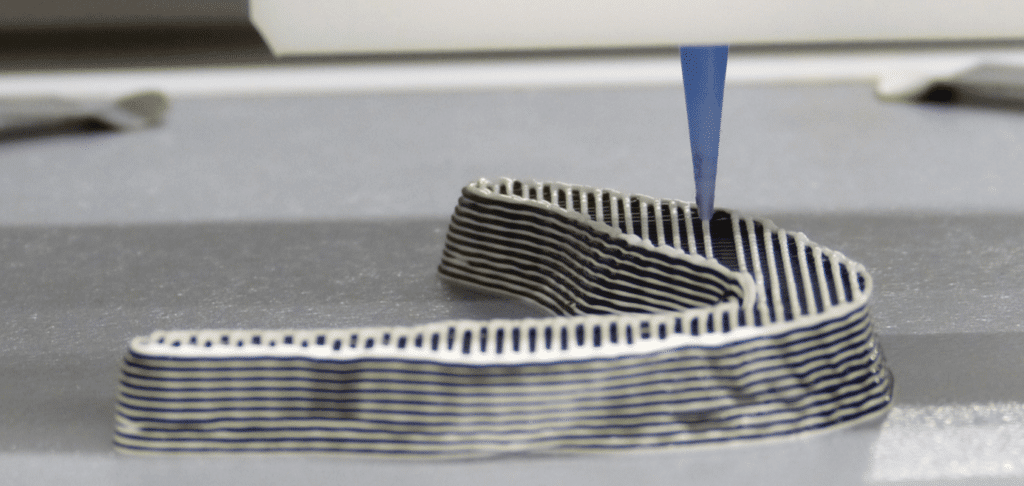

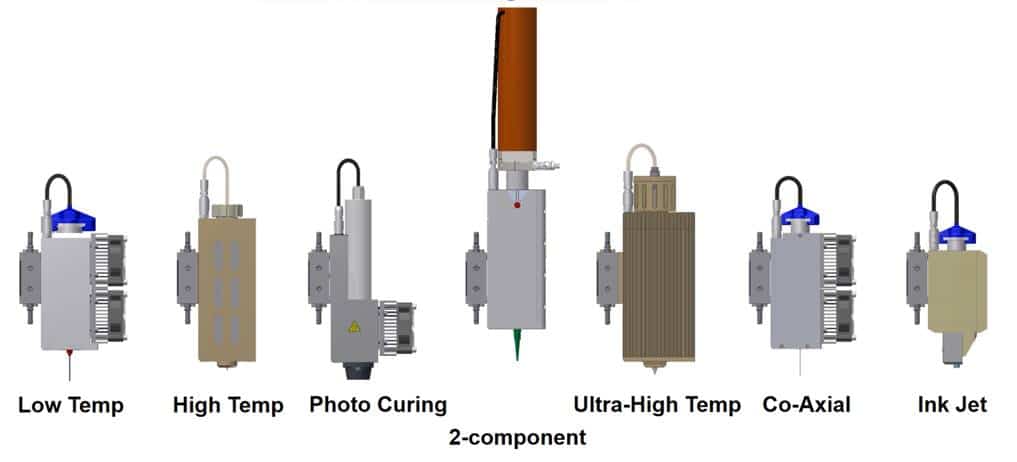

Madalyne Ridella: The 3D-Bioplotter is a rapid prototyping machine specially designed for the fabrication of scaffolds using biocompatible materials for biomedical applications. It is an extrusion-based system, where a liquid is dispensed from a syringe, using air pressure, while moving the syringe in all three dimensions. The 3D-Bioplotter is unique because it can process a wide variety of materials such as thermoplastics, ceramic/metal pastes, hydrogels and more. A recent upgrade of the 3D-Bioplotter’s photo-curing head now enables up to five wavelengths or combinations of wavelengths in a single print, while a new low-temperature ink jet head dispenses low viscosity hydrogels through a non-contact process.

How is the 3D-Bioplotter enhancing healthcare delivery? Can you give us some examples of real-world applications?

Madalyne Ridella: The 3D-Bioplotter can be used for a wide range of medical applications, including bone regeneration, cartilage regeneration, soft tissue biofabrication, controlled drug release, cell printing, and organ printing. In 2017, researchers at Northwestern University in Illinois used the 3D-Bioplotter to fabricate artificial mouse ovaries. These were placed in sterile animals, which were able to reproduce and had their normal hormonal functions necessary for breastfeeding restored. This will hopefully one day lead to the bioprinting of human ovaries.

EnvisionTEC also develops materials for 3D bioprinters. Can you tell us a little about these? Is there anything particularly innovative about them?

Madalyne Ridella: The lack of biologically active materials, also called “bioinks”, is a key issue that limits the ability to produce engineered tissues, tissue interfaces, and functional organs. Pushing the bioink boundaries, EnvisionTEC has developed materials for soft tissue and bone/cartilage engineering. Our soft-tissue materials include a medical-grade silicone approved for short term use in the body, a gelatin-based hydrogel mixture for cell printing, and a two-component silicone for research. Our bone/cartilage materials include self-setting hydroxyapatite and medical and research-grade polycaprolactone (PCL).

How do you see 3D bioprinting evolving in the near future? Do you have any more products or product evolutions that you can tell us about?

Madalyne Ridella: The hospital of the near future will incorporate revolutionary technologies that will transform healthcare, delivering highly automated and personalized patient solutions. These will lead to lower healthcare costs, improved access to the best treatments, and significantly better health outcomes. Biofabrication with 3D bioprinting will play a key role in this evolution, producing patient-specific replacement tissue constructs that restore biological functions and health in a highly efficient and customized way.

As bioprinting evolves, it will become possible to use a patient’s own cells to 3D print skin and bone grafts, organ patches, and even full replacement organs. A range of different 3D-bioprinting approaches are being taken: from extrusion-based polymer fabrication with cellular-level resolution (such as the 3D-Bioplotter) to 3D laser-printed constructs. EnvisionTEC’s cutting-edge print head technology can make the printing of functional organs a reality by diversifying the range of biomaterials customers can use.