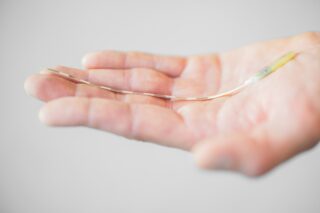

Medical professionals are now moving forward on 4D-printed objects, generating structures that change shape and functionality without external intervention. We might soon see 4D-printed cardiac stents, but only time will tell.

Although 4D printing surfaced a few years ago, its description remains debatable. Stratasys defines it as “a transformation from one shape to another directly off the 3D printer.” Dr. Marc in het Panhuis from Wollongong University presented his work at the 3D Medical Expo 2016. Following Stratasys’ explanation, his team 4D printed a valve that opens and contracts when in contact with water, depending on temperature. Panhuis explained:

“The valve we made operates autonomously, i.e. without the need of a control unit or switch to open or close the valve. For medical applications, the valve would have to be shrunk and then it could be used for drug delivery when the need arises without the patient or doctor having to take action.”

Another Dimension Added—Time

Stephen Gray, cofounder of Ourobotics, explained to MedicalExpo during 3D ME 2016:

“The technology has not changed. But the use of materials, like shape memory alloys and electroactive polymers, allows for more advanced 4-dimensional printing.”

“We’ve been discussing 4D printing a lot,” Drs. Lorenzo Moroni and Carlos Mota at MERLN Institute told MedicalExpo.

“Everything changes with time. If you really want to call it 4D printing, it will have to be something that changes with time but that happens during the printing process.”

Panhuis agreed:

“We don’t actually do 4D printing. We 3D print shapes and add another dimension—time.”

He said the use of cellular bioinks is the closest example of true 4D printing today.