Our reporter Marcia Adair toured the IDS dental fair to discover what’s trending in the dental industry. We get a glimpse of solutions for biocompatible bone regeneration, the world’s first handheld robotic drill, Micro Factory’s 3D printer, and more.

At the International Dental Show (IDS) in Cologne, the future of dentistry came into sharper focus. We had a walk through the halls and found two main themes emerging like 3D printed dentures, AI, robotics, and bio-developments. No surprise, considering these are global mega-trends. What was a surprise was finding another global mega-trend, namely, natural and sustainable products, at the stand of one of the oldest companies at the fair.

Here’s what you need to know about biocompatible bone regeneration, the world’s first handheld robotic drill, Micro Factory’s 3D printer, and more.

Biocompatible Bone Regeneration: The Push for More Effective and Natural Solutions

Botiss Bio Materials showcased the NovaMag membrane, a fully resorbable membrane for guided bone and guided tissue regeneration with a feature unique in the market.

“The NovaMagis special because of its dual functionality—it maintains bone structure during healing and resorbs naturally over time, eliminating the need for removal surgeries,” Dr. Sascha Böhm, Product Manager, explained.

Additionally, Botiss launched maxgraft +HyA. The hyaluronic acid added to their maxgraft allograft granules offers improved handling and application comfort for any treatment of bone defects as well as surgical procedures.

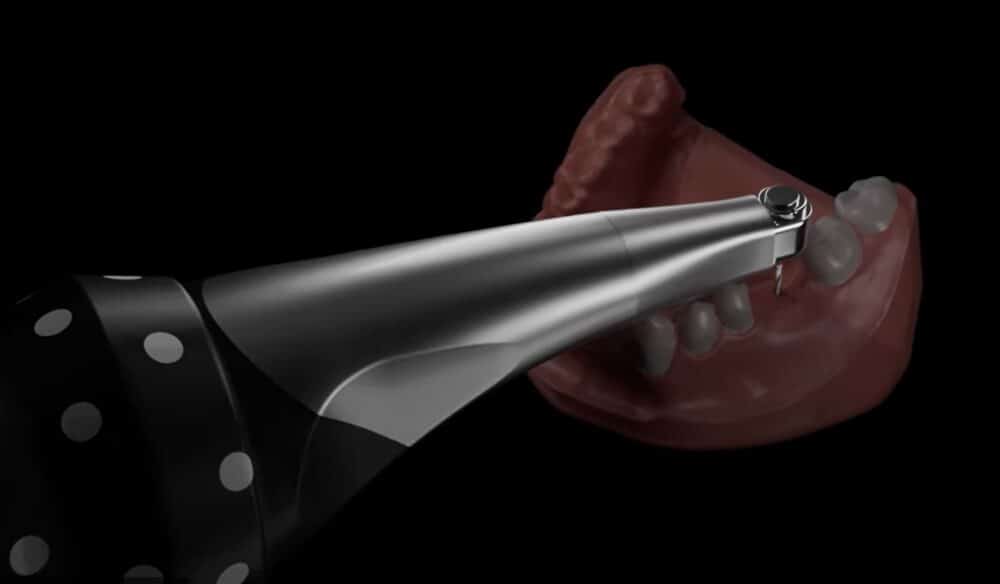

World’s First Handheld Robotic Drill: Precision and Efficiency

The next product to catch our was the world’s first robotic hand drill. Produced by Atomic.ai, the drill promises enhanced precision in challenging environments

“The robotic handpiece assists in positioning the drill, ensuring it targets the correct implant site with unrivaled accuracy,” shared a representative from Atomic.ai.

Unlike traditional drills, which depend on a steady hand, the robot adjusts the tool’s position in real time, allowing even less experienced professionals to perform with greater precision.

In addition to better outcomes, the handpiece improves efficiency by significantly reducing procedure time. Features such as four-directional movement (X, Y, Phi, and Theta), make it a valuable tool for implants, facilitating increased patient safety and faster recovery times.

Micro Factory: Redefining Resin 3D Printing

The Munich start-up Micro Factory has developed a fully automated resin printer that requires zero manual intervention for engineering, dental, and medical applications.

“You just send the file, and the machine handles everything—printing, cleaning, curing, and ejecting the part, running autonomously 24/7,” said Simon Rost, Micro Factory lead software engineer.

The main application currently is in the lab, where the autonomous operation is combined with a capacity to 50 build plates per printer offers a significant boost in high-volume production efficiency. At €29,000 per unit, Rost calculated that practices printing “at least 13 splints per month” would also be well positioned to realize the benefit of in-house production.

Micro Factory is an open platform tool, meaning users can work with whichever tools or materials the user is currently familiar with. The printer is compatible with any CAD/CAM system and scanner and can print using almost any material. Rost said:

“We do have a recommended set of materials, but it is possible to use something that you already have in your lab or practice.”

On the output side, Micro Factory can produce models, splints, crowns, temporary crowns and try-ins.

“Curing for non-biocompatible products like models happens inside the printer itself. By the end of 2025, biocompatible products will also be possible with the Power Cure Box, which supports Stage II cleaning with oxygen inhibition.”

Biocompatible Dentistry: A Natural Approach to Filler Products

Sometimes, to go forward, you first need to go back. Since 1892, Hoffman’s has been developing dental products made from natural ingredients, the most well-known of which is a phosphate cement. This year, they were showing a range of natural filler products, such as tooth cements, endodontic and pipe-capping materials made from zinc oxide, olive oil, castor oil, copal, and propolis.

“Nowadays we are finding out more and more that all these composites and resins are not as unharmful as we thought,” explained a representative at the stand. “Our products, are becoming more popular not just because of their effectiveness but also because they significantly reduce the risk of allergies compared to traditional composite resins.”

The whole-ingredient products are also a good option for patients who are pregnant.

“In this time patients often have problems with their gums because they get inflamed faster. We have a several very effective oils you can apply directly in the pocket as an alternative to chlorhexidine.”

As patients and professionals alike become more aware of the environmental impact of synthetic dental products, the demand for natural alternatives is expected to rise significantly.