With the rise of 3D printing in the healthcare sector, there are ongoing discussions about the U.S. Food and Drug Administration’sregulation strategy concerning 3D printed devices. MedicalExpo talked with Matthew Di Prima, Head of the Additive Manufacturing Working Group at the FDA’s Center for Radiological Devices and Health.

MedicalExpo e-magazine: How does the FDA control the quality of 3D printed devices?

Matthew Di Prima: Devices constructed using 3D printing technology are subject to the same regulatory review standards as devices constructed using traditional manufacturing practices. However, 3D printing techniques have different technical considerations than standard manufacturing. Furthermore, traditional manufacturing settings have design controls and systems, such as for complaint handling, that 3D printing settings may not have. That is why devices manufactured using 3D printing technology may need additional or different testing than what is normally performed for products that are manufactured using traditional (subtractive) techniques. As 3D printing technology develops, the FDA may provide further clarity on quality control issues such as material qualifications and sterility.

Devices manufactured using 3D printing technology may need additional or different testing than what is normally performed. Regarding 3D printing materials, materials used in formulating or constructing medical products are evaluated for safety or effectiveness within the context of the overall safety and effectiveness of the medical product for its intended use. Note that the FDA does not clear or approve materials for medical devices and/or products, it clears or approves finalized medical devices and/or products. Software used in conjunction with 3D printing is regulated through the same pathways as other medical device software. The specific pathway will depend on the intended use and risk level.

ME e-magazine: 3D printing often relates to personalized medicine. How does it impact the FDA certification process?

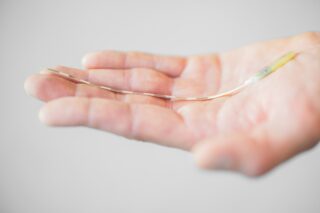

Matthew Di Prima: Patient-matched devices (a form of personalized medicine) or devices made from a common design and adjusted to more closely fit a patient’s anatomy or physiology, are currently regulated through FDA’s existing regulatory pathways. The device manufacturer must still show the devices meet the safety and effectiveness criteria as required by the type and class of that device.

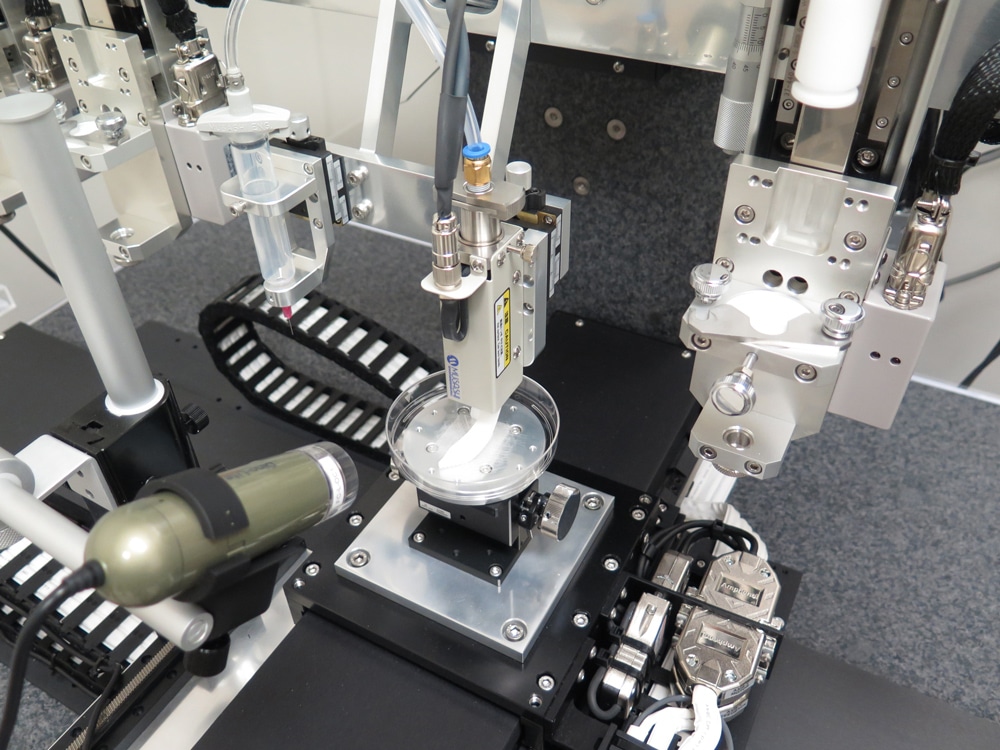

ME e-magazine: How do you deal with medical manufacturing facility equipped with 3D printers?

Matthew Di Prima: The FDA is considering regulatory options for individuals who would like to print medical devices at home. 3D printers to fabricate medical devices are generally considered to be manufacturing equipment subject to Good Manufacturing Practice/Quality System regulations but are not considered to be medical devices themselves. The objects that are fabricated by these printers are considered to be medical devices if they are intended for use as specified in the Act (FFDCA) or are labeled or promoted for such use. The FDA is also currently considering regulatory options for individuals who would like to print medical devices at home or other user sites and anticipates providing information in the near future.

ME e-magazine: 3D printing opens new challenges in terms of biocompatibility, sterility and cleaning. How should these challenges be handled?

Matthew Di Prima: Biocompatibility, sterility, and cleaning are concerns with all medical devices. The FDA held a workshop in October of 2014 on 3D printing in which these concerns were discussed with industry and academia. Additionally, the FDA is conducting research to better understand how these challenges vary for different 3D printing technologies and is working to develop a draft technical guide to assist the industry in addressing these concerns. The device manufacturer must show that their product has no safety or effectiveness issues regarding biocompatibility, sterility and cleaning.