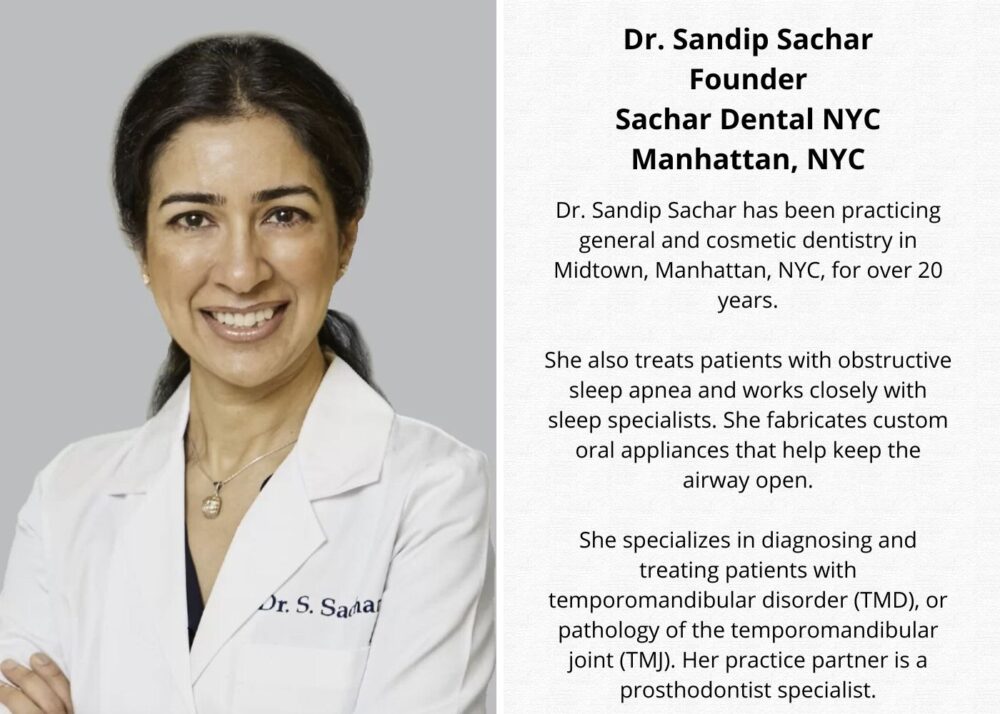

Dr. Sandip Sachar, Manhattan dentist, provides start-to-finish procedural details for creating a digital smile design.

In a hurry? Here are the four main steps according to Dr. Sandip Sachar:

- Data capture: High-resolution photos and digital scans of a patient’s mouth

- Oral scanner and imaging software to create a 3D picture and movable model

- Print 3D impressions in-house, if possible, to reduce turnaround time

- Import all the data into a digital smile design software and review it with patients

The first step in planning cosmetic dentistry cases often involves using high-resolution photos and digital scans of a patient’s mouth; I do this to create a 3D simulation of the patient’s current status and proposed future smile. This allows patients to preview results before the procedure begins and contributes to a collaborative treatment plan that sets expectations and goals.

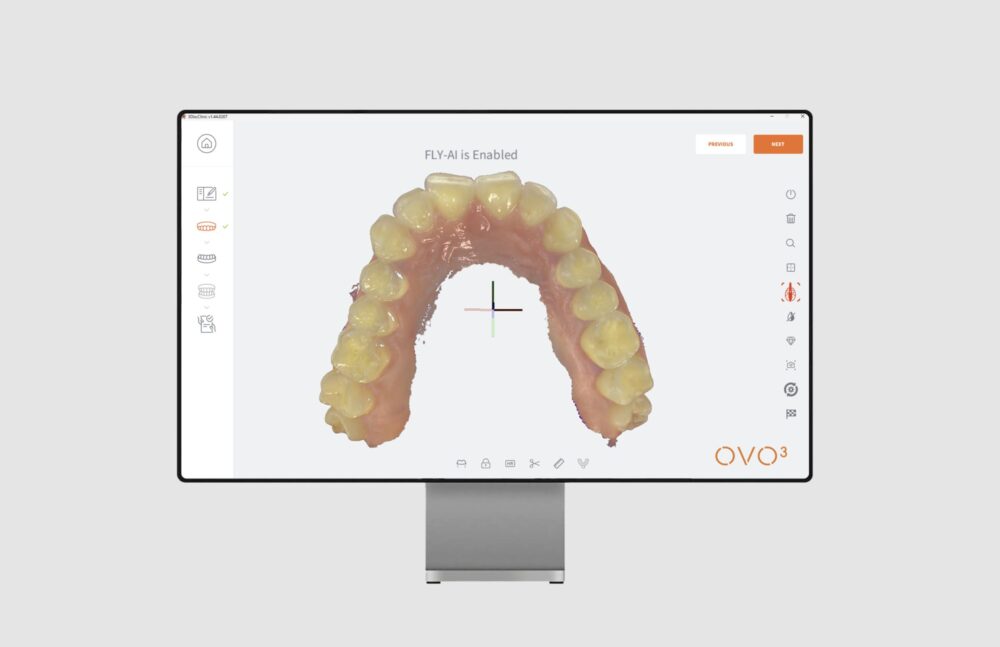

In practice, digital smile design entails an extensive workflow. It starts with data capture through full-face photos of the front, profile, three-quarter views, and dynamic smiling pictures. I use the iTero 3D oral scanner and imaging software to create a 3D picture and movable model of the patient’s anatomy.

We can use digital smile design CAD/CAM software to generate 3D mockups to visualize the before and after 3D pictures of the patient’s mouth and manipulate the images in all directions.

Learn more: The #1 digital smile design software solution: Increase Case Acceptance and Deliver Predictable Outcomes

Combining Interdisciplinary Planning and Reducing Miscommunication

A complete smile makeover can combine interdisciplinary planning with any combination of orthodontics, periodontics, tooth implants, veneers, resin bonding, teeth whitening, and any other cosmetic dental procedures. Once approved in the software, I can export the design to my laboratory for any combination of veneers, ceramics, or composite fabrication. I also have the option of in-office milling or 3D printing.

Designing the smile digitally reduces miscommunication with patients such that they can visualize shade, length, and tooth axis before treatment starts. This minimizes irreversible prep, allowing conservative enamel removal because contours are pre-validated. It improves long-term aesthetics, including incisional edge position, occlusion, and facial proportions that are all optimized to improve outcome and reduce potential complications.

Cone Beam CT (CBCT): Planning for Tooth Implants

High-resolution CAT scan allows me to visualize the patient’s bones, oral structures, and airway. This high-tech imaging allows me to get submillimeter accuracy. The field of view can be limited to reduce the amount of radiation exposure or a full arch and airway to visualize more anatomy. Recent advancements in CAT scan technology have allowed for excellent image quality and less radiation than older machines. The CAT scan software allows for 3D imaging of the oral anatomy and bone structure.

I use CBCT to plan for tooth implants. CAT scans are also an effective way to diagnose vertical root fractures, which are usually not evident on traditional X-rays. I am also able to visualize the accessory canals and resorptive defects that are invisible on X-ray.

CBCT is also essential in airway and sleep apnea assessments. Volumetric analysis of the nasal and pharyngeal spaces can guide oral appliance titration. CBCT is also essential in the diagnosis of TMJ. CAT scan allows me to see cysts, impacted teeth, condylar degenerative changes, and sinus pathology. Reviewing these in 3 dimensions allows for more predictable diagnosis and treatment options.

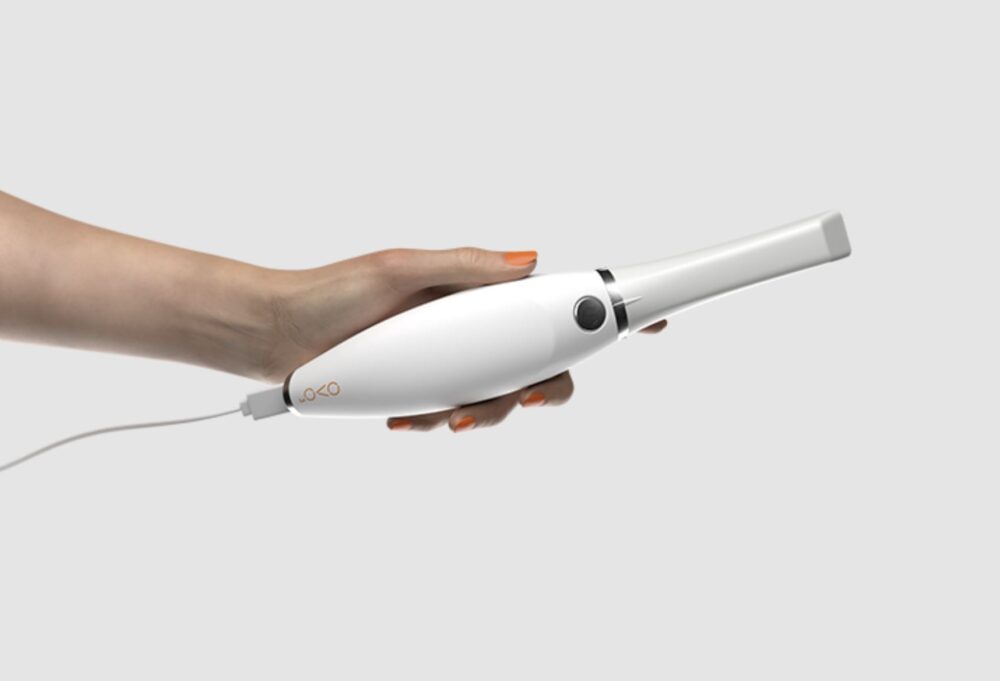

Intraoral Cameras: A Diagnostic Aid

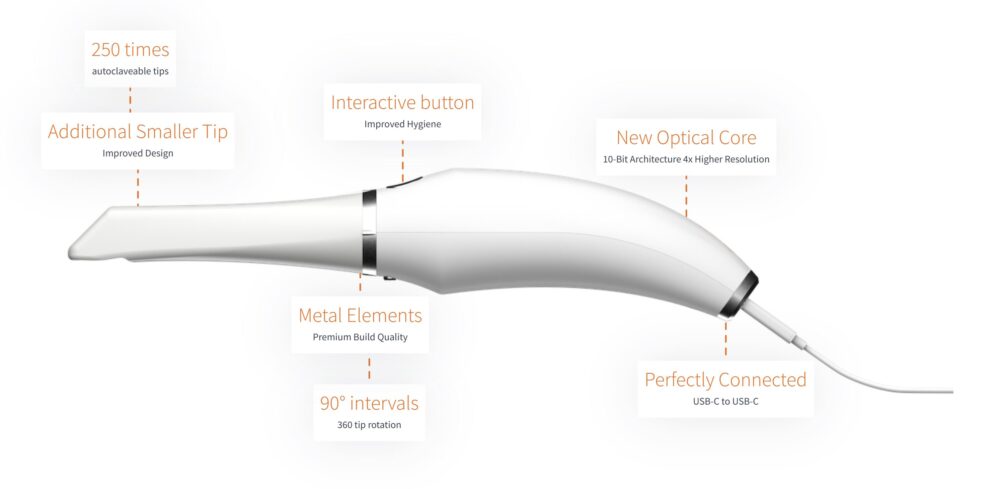

Technology in digital color photography inside the mouth has come a long way. Intraoral cameras are high resolution, from 1080p to 4K sensors. They have built-in bright LED lamps that allow for excellent imaging. The camera head is just a small 9 mms that allows for easy access to the entire mouth.

Digital oral cameras act as a diagnostic aid. They can magnify craze lines, leaking margins, and detect early cavities that could be missed in traditional visual exams. Oral cameras are also excellent for documentation. High-resolution still images are automatically integrated into the dental chart, supporting insurance preauthorizations and allowing for enhanced medical records.

Oral cameras are also an excellent tool to show patients what I am seeing during their exam. I show patients the amount of plaque present, fractures, bleeding gums, and other oral pathology. I have a large monitor mounted on the wall so I can easily show patients these images. This dramatically increases patients’ acceptance and understanding.

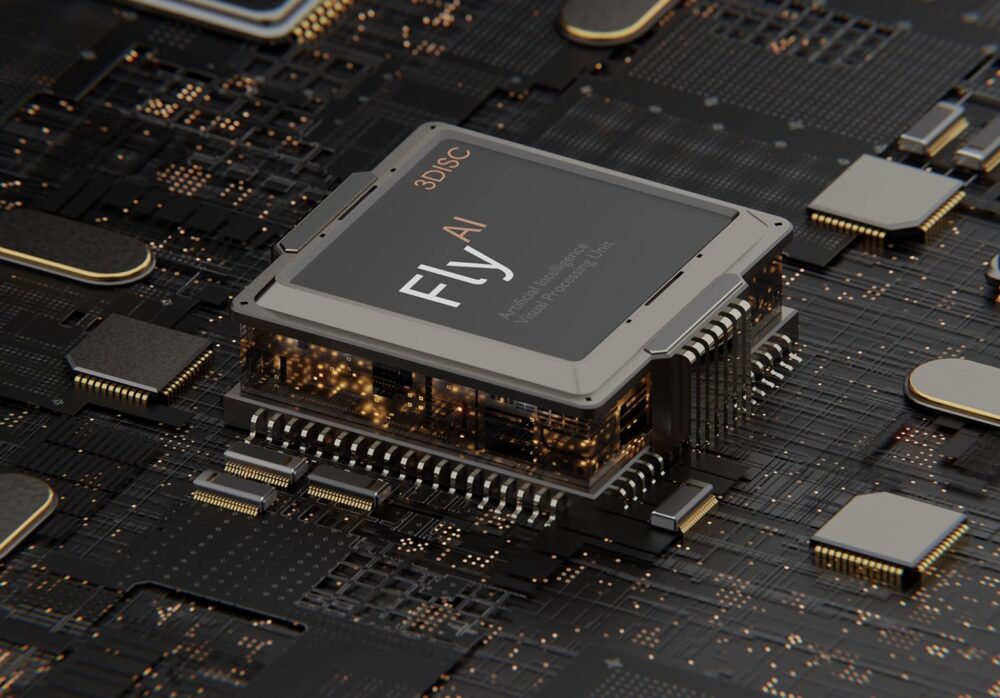

Practical design changes include a rotational tip system that can be adjusted in 90-degree intervals. The tips are autoclavable up to 250 cycles. The scanner connects via USB-C to USB-C. On the software side, 3DISC has integrated “Fly AI” algorithms designed to eliminate stitching errors by automatically detecting and removing unwanted soft tissue and foreign objects like gloves or the patient’s tongue.

3D Digital Oral Scanners for Accurate Impressions

Before digital scanners, we relied on traditional polyvinyl siloxane (PVS) or alginate impressions. These were poured into a tray and placed in the patients’ mouths. Accuracy was highly dependent on proper tray fitment and material handling, and setting time. Distortions regularly occurred during removal and pouring and were highly dependent on having perfect technique and timing.

Intraoral digital scanners are capable of capturing high-resolution images of the teeth and mouth soft tissues. Accuracy is consistent and unaffected by variables such as temperature, humidity, timing, and material storage. Digital scans can typically be achieved with sub-20 µm precision, significantly outperforming traditional impressions.

Intraoral digital scanning is more patient-friendly. Traditional impressions were often uncomfortable, especially for patients with a strong gag reflex. Digital scanning is more comfortable. A small wand-like scanner is moved across the mouth quickly to achieve accurate imaging of the teeth and mouth structures. There is no mass, no pressure, no gagging, and little to no discomfort.

Traditional impressions require time to mix the materials, wait for them to set, and pour stone models. Often, there were errors such as bubbles, voids, or tears. Occasionally, impressions needed to be repeated to get accurate molds. Once completed, these impressions are shipped to the lab, adding to wait time, versus digitally sending 3D scans. Digital scanning can be sent electronically without waiting time. Digital scanning produces instant 3D model scans that can be reviewed or corrected in real-time.

3Shape unveiled the TRIOS 6 at IDS 2025, transforming the scanner from a digital impression tool into a comprehensive diagnostic platform powered by sophisticated AI.

A newcomer to the digital dentistry space, Korean brand arcreal made their debut at IDS 2025 with the launch of their arcscan intraoral scanner alongside their arcgrid digital platform.

In-house Milling 3D Printing to Cut Lab Turnaround Time

CAD/CAM software has come a long way in designing oral restorations. After an intraoral scan, the software AI can auto-propose margin lines and accurately suggest contact points along the anatomy. Often, the milling machine is either a 4 or 5 axis mill that cuts monolithic lithium-disilicate or zirconia blocks with accuracy down to 25 µm.

We can crystallize, stain, and glaze restorations in the office. A rapid oven can crystallize zirconia in 15-20 minutes, followed by using staining kits to customize the shade. Using resin cements with immediate dentin setting, patients can leave with a definitive oral restoration on the same day. This eliminates temporary crowns that can reduce sensitivity and contamination. It also allows for fewer office visits, fewer anesthetic injections, and less in-chair time commitment.

Similarly, we can cut lab turnaround time by producing 3D prints in-house. Instead of waiting weeks for the prints, we can have them done the same day. We can 3D print clear liners for orthodontics, surgical guides for implant positioning with approximately 0.5 mm accuracy, indirect bonding trays for braces, nightguards, and fully printed temporary crowns and bridges using biocompatible resin. Advancements in materials provide traceability and comply with sterilization protocols that meet FDA ISO standards. This ensures patient safety and regulatory compliance.

Formlabs highlighted two major developments at IDS 2025 – their Open Material Mode for the Form 4B and the launch of their Form Cure (2nd Generation).

HeyGears showcased further advancements in their multi-material fusion technology at IDS 2025. This innovative approach to dental 3D printing generated significant interest, with demonstration samples illustrating how their DLP technology can achieve multi-color prints from a single resin system.

In Short: Digital Smile Design for Happy Patient Endorsement

In summary, a typical cosmetic case starts with intraoral scanning, photos, and sometimes cone beam CT. We import all the data into digital smile design software to produce a 3D markup, review it with our patients on screen, and then plan the objective outcome. After approval, we 3D print or mill the restorations in the office or send them to our specialized laboratories.

Intraoral camera pictures and periodic scans help to document before, during, and after outcomes. Oftentimes, patients share their before-and-after outcomes on social media. A happy patient endorsement goes a long way in the form of marketing to reach future patients.