The sustainable, solvent-free new detectors can register radiation doses 50 times lower than today’s standard technologies, opening new horizons for medicine, industry, and security.

A group of researchers from the Helmholtz-Zentrum Berlin für Materialien und Energie (HZB), in Germany, led by Professor Olena Maslyanchuk, has discovered that new bismuth-based organic-inorganic hybrid materials show long-term stability as X-ray detectors and are significantly more sensitive than the X-ray detectors broadly used today—to the point of detecting X-ray doses nearly 50 times lower than those detectable by traditional materials such as amorphous selenium or CdZnTe [the alloy cadmium zinc telluride].

Halide perovskites—a unique class of exceptional photosensitive semiconductors—have been tested as X-ray detectors with very good results in recent years. The two specific bismuth-based halide perovskite materials explored at HZB have as their formulas [(CH3CH2)3S]6Bi8I30 and [(CH3CH2)3S]AgBiI5.

How X-rays Work

X-ray is a form of high-energy electromagnetic radiation that can pass through most objects, including the human body. Whenever a radiograph is made, the patient is positioned in a way such that the part of the body being imaged is located between the X-ray source and the X-ray detector. When the machine is turned on, X-rays travel through the body and are absorbed in different proportions by different tissues, depending on the radiological density of the tissues they pass through.

This radiological density is determined by both the density and the atomic number (meaning, the number of protons in an atom’s nucleus) of the material being imaged. Our bones, for instance, contain calcium, which has a higher atomic number than most other tissues. That is the reason bones readily absorb X-rays and therefore produce high contrast on the X-ray detector, appearing whiter than other tissues against the black background of a radiograph. Conversely, X-rays travel more easily through less radiologically dense tissues, such as fat, muscle, and air-filled cavities like the lungs. That is why these structures appear in shades of gray on a radiograph.

The Improved Sensitivity of the Bismuth-based Materials

Maslyanchuk’s research materials achieve this higher sensitivity through a combination of key physical and structural properties. First, they contain high atomic number elements, which enhance X-ray absorption efficiency. Second, they exhibit excellent charge transport characteristics. Photoconductive gain is also frequently observed, further amplifying the signal at low dose rates. In addition, by optimizing the crystal structure and grain boundary chemistry of the substances used, the scientists at HZB are able to significantly reduce noise and dark current—two major limitations in conventional detectors.

To assess the long-term stability of the new detectors, Maslyanchuk’s group evaluated them under a range of real-world stress conditions, such as ambient shelf-life testing over an 18-month period, prolonged electrical bias stress (where devices were operated continuously under high voltage), continuous X-ray exposure, and high-intensity pulsed synchrotron irradiation (which is a way to simulate extended clinical and industrial use while verifying resistance to radiation-induced degradation).

The Environmental Advantages

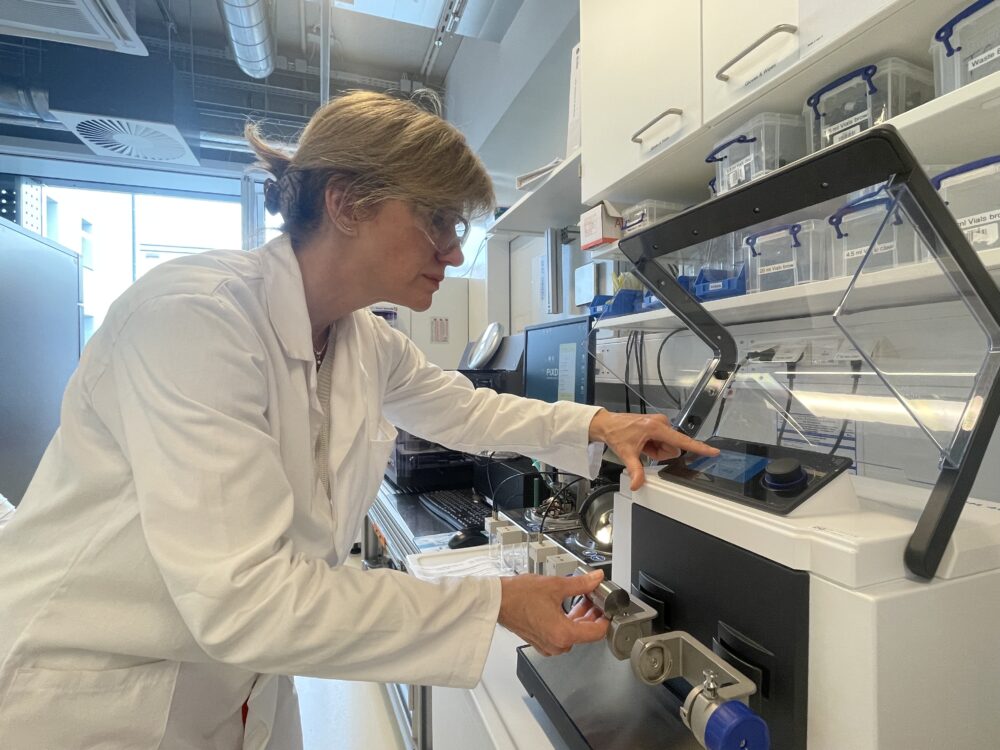

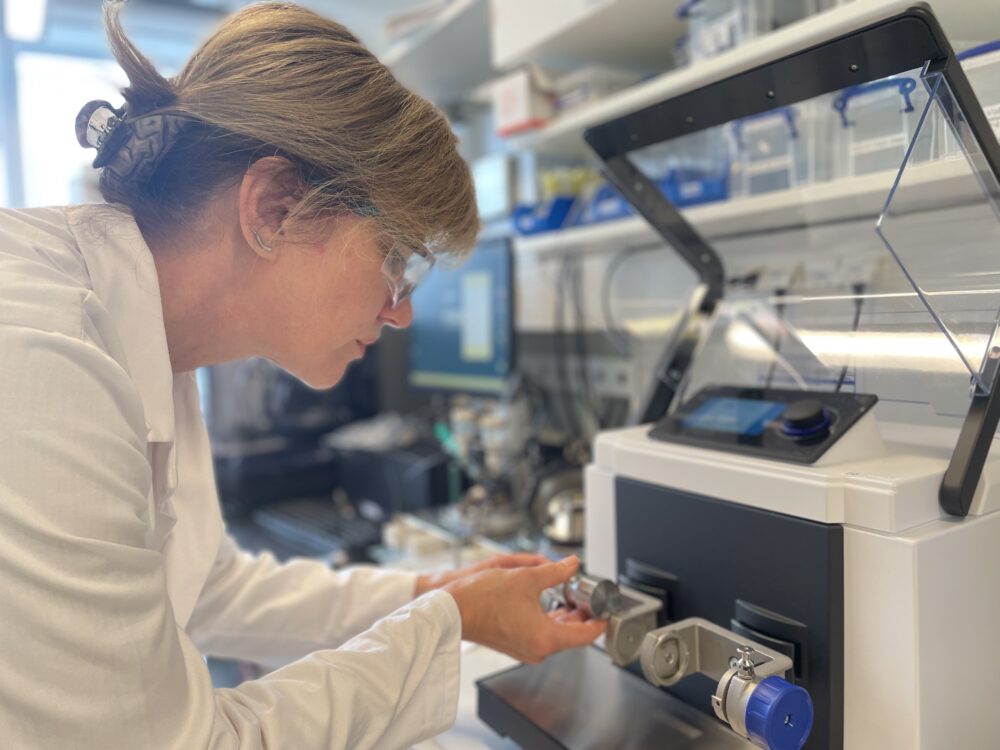

Not only do the HZB’s bismuth-based materials enable lower X-ray doses for patients but they can also be produced without solvents. That is possible thanks to a method called ball milling, a mechanochemical synthesis process that is established in industry, environmentally friendly, and scalable. Basically, ball milling consists of the production of polycrystalline powders that are then pressed into dense pellets. HZB’s ball milling process is carried out in collaboration with Bundesanstalt für Materialforschung und -prüfung (BAM)—or Germany’s Federal Institute for Materials Research and Testing—expert Franziska Emmerling.

“The solvent-free synthesis process, particularly ball milling, significantly improves the sustainability of detector production in several ways. First, it eliminates the use of hazardous organic solvents, which are common in traditional wet-chemical methods and pose risks to both health and the environment. This reduces the need for solvent disposal and complex purification steps. Second, the process is energy-efficient and operates at room temperature and ambient pressure, lowering the overall carbon footprint. It also simplifies material handling and minimizes chemical waste, making it easier to implement cleaner, safer, and more cost-effective manufacturing,” Maslyanchuk told MedicalExpo e-Magazine.

The Challenges

Transitioning from lab-scale to industrial-scale does present certain challenges, though. A key issue is process reproducibility, as, at larger scales, it becomes more difficult to maintain uniform particle size, phase purity, and stoichiometry (which is the determination of the proportions in which elements or compounds react with one another).

Another challenge is ensuring material homogeneity and consistent performance across different batches. That said, industrial-scale ball milling systems are already well established in the ceramics and pharmaceutical sectors, making the pathway to scaling feasible.

“Our aim is to adapt these existing technologies with optimized parameters tailored to perovskite-based detector materials, enabling efficient and reproducible large-scale production,” Maslyanchuk explained.

Beyond the Medical Field

These detectors being developed by Maslyanchuk’s group also have broad potential beyond medical imaging. After all, their high sensitivity, low detection limits, and long-term stability make them excellent candidates for security screening at airports, where rapid and accurate identification of low-density materials is crucial, and in industrial inspection, where they could deliver more precise imaging of materials and components while reducing radiation exposure.

“We are actively exploring new application areas with prospective partners and building partnerships to move toward pilot-scale manufacturing and real-world testing of our detectors. A central element of this effort is our collaboration with a local X-ray detector company, with whom we are already engaged in technology transfer activities and third-party validation following our internal characterization phase. In addition, we are exploring partnerships in scientific instrumentation and security screening sectors to assess application-specific performance and regulatory requirements. At the same time, we welcome additional industry partners to explore alternative application areas and co-develop pilot deployments that validate performance, integration, and regulatory fit in their markets,” Maslyanchuk said.

Olena’s research has been supported by the Deutsche Forschungsgemeinschaft (DFG) within the Walter Benjamin Programme (SENSE 546734407), as well as by the Helmholtz Initiative for Refugees through the Initiative and Networking Fund of the President of the Helmholtz Association. Her work in this field would not have been possible without this support after her relocation to Berlin in 2022, following the escalation of the Ukrainian–Russian war.